March 13, 2024

By: Vandana Gombar, BloombergNEF Senior Editor – Global Policy

The growing use of batteries will require a jump in recycling. A startup is promising a technology that will economically recover key transition metals from the ‘black mass’ of shredded dead batteries at smaller scale plants.

“The winner in this industry will be the one offering the highest efficiency and the best-in-class economics,” Preston Bryant, founder and executive chairman of Momentum Technologies, told BloombergNEF. “We are able to offer that with our modular extraction technology.” It can extract lithium, nickel, cobalt and rare earth elements, among other metals.

Scientists at Oak Ridge National Laboratory developed the membrane-based solvent extraction or MSX process to recover metals from rare earth magnets and lithium-ion batteries. Momentum Technologies holds an exclusive license for it globally.

“Using a membrane-based system allows us to build a very modular technology, and that allows us to do some unique things in the world of battery recycling,” said Bryant. “We can physically be located closer to where the batteries are being shredded.”

“We are a technology company working in the battery recycling space.” – Preston Bryant,

Founder & Executive Chairman

MSX is a play off traditional hydrometallurgy – using chemicals to break down the battery to recover the metals. The membrane-based technology allows the use of just a fraction of the chemicals used in typical hydrometallurgy, and re-use them multiple times. It is also efficient in the use of energy, using a minimal amount of temperature and pressure.

“We are trying to change the dynamics of the market here,” Bryant said, “by building smaller facilities using readily available parts rather than large billion-dollar facilities.”

A demonstration plant with the capacity to process about 200 tons of black mass is coming up in Carrollton, Texas. It will be ready in about two months.

The first plant will be located in Ohio – a full scale facility with the capacity to process 1,500 tons of black mass per year next to Cirba Solutions. It is expected to be operational by the second quarter of 2025.

Momentum has raised $20 million so far. There was a round of investment from TechMet, the critical minerals investment company, and from Freestone, a portfolio company of private equity firm Tailwater Capital. It plans to raise Series B funding in a few months.

“Many startups like Nth Cycle and Green Li-ion are trying to address this fast-growing market,” said BNEF analyst Andy Leach, who sees battery material available for recycling jumping 10-fold by 2035. See more in BNEF’s latest Lithium-Ion Battery Recycling Market Outlook.

“Raising funding is the number one challenge. We are in a multi-year low now on venture capital and startup funding,” said Bryant.

The contraction in climate-tech funding has however been less than the overall reduction in funding for startups. Read more in: Over $50 Billion Flow to Climate-Tech Startups in 2023.

The fact that the metals market is at a historic low is another challenge. The value of what is retrieved is now a fraction of what it was a year ago. However, as BNEF’s metals analysts Allan Ray Restauro puts it: “What is certain is long-term demand growth.”

Recycling will likely end up being more of a local industry with some jurisdictions proposing a ban on movement of black mass across the border. It is also expensive to ship around the world.

Bryant also said the following on:

Quality of ‘black mass’

I like to refer to black mass as the new oil. We have different kinds of oils – light-sweet or heavy or sour. At some point, this black mass will be similarly graded on its metal content. Typically, 50% of the black mass is carbon.

Breakthrough technology

We don’t have our third-party validation yet, but we are working on our lifecycle analysis. We are confident that our technology is extremely efficient compared to competitors.

This technology is a jump on the innovation curve and not just a small fractional increase in hydrometallurgy capabilities.

Small-scale versus large plants

The traditional metals recovery process utilizing solvent extraction demands hefty capital investments, large feedstock quantities, significant process chemical volumes, and substantial energy consumption. This technology excels in mining. Momentum’s MSX system adjusts seamlessly to varying feedstock volumes, ensuring swift ROI even in small-scale operations. Our MSX system configurations are adaptable to changing battery chemistries and can process rare earth from magnets and various other materials without additional equipment.

Sales deal

We have signed a deal with our investor Techmet- Mercuria. They are going to market and sell all the metals we retrieve and produce.

Metals price volatility

The slide in the value of metals like lithium creates a ripple effect throughout our business, impacting everything from procurement and production to investment and market demand. It underscores the importance of…implementing strategic measures to mitigate the adverse effects on our operations.

Competitive landscape

There is a lot of competition for battery recycling because there is a lot of value in the batteries. The thing it comes down to is – who has the best-in-class economics. We are the only ones working on the MSX technology commercially. There are only a few companies working on modularity.

Some states are more favorable. A lot of companies are going to build batteries in Nevada and California.

—

You can also find this article on BloombergNEF’s Terminal, here.

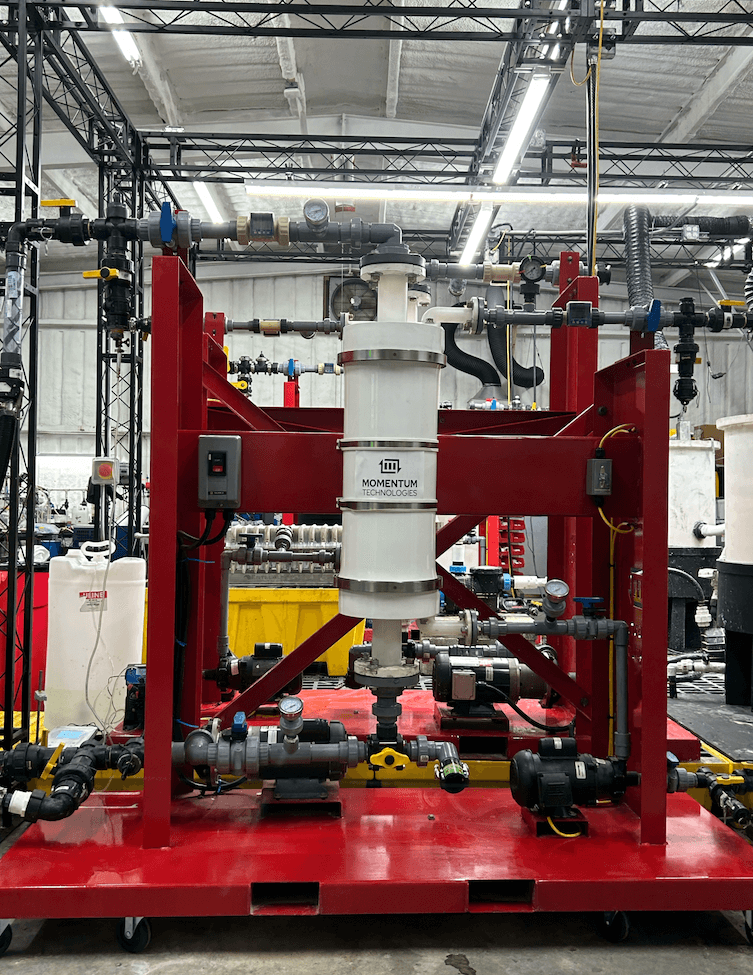

MSX skid. Six of these will be used in the Texas demonstration plant.